лӢЁмқј мғӨн”„нҠё 분мҮ„кё° лё”л Ҳмқҙл“ң мһ¬нҷңмҡ© л°Ҹ нҸҗкё°л¬ј кҙҖлҰ¬ мӮ°м—…м—җм„ң мӨ‘мҡ”н•ң м—ӯн• мқ„ н•©лӢҲлӢӨ. мқҙлҹ¬н•ң лё”л Ҳмқҙл“ңмқҳ м„ұлҠҘ, лӮҙкө¬м„ұ л°Ҹ нҡЁмңЁм„ұмқҖ м ңмЎ°м—җ мӮ¬мҡ©лҗҳлҠ” мһ¬лЈҢм—җ нҒ¬кІҢ мўҢмҡ°лҗ©лӢҲлӢӨ. м Ғм Ҳн•ң мһ¬лЈҢлҘј м„ нғқн•ҳл©ҙ кёҙ мӮ¬мҡ© мҲҳлӘ…, лҶ’мқҖ м ҲлӢЁ м •л°ҖлҸ„, к·ёлҰ¬кі к°ҖлҸҷ мӨ‘лӢЁ мӢңк°„ к°җмҶҢлҘј ліҙмһҘн• мҲҳ мһҲмҠөлӢҲлӢӨ.

к°ҖмһҘ мқјл°ҳм ҒмңјлЎң мӮ¬мҡ©лҗҳлҠ” мҶҢмһ¬ мӨ‘ н•ҳлӮҳлҠ” лӣ°м–ҙлӮң кІҪлҸ„мҷҖ лӮҙл§ҲлӘЁм„ұмңјлЎң мң лӘ…н•ң кі нғ„мҶҢк°•мһ…лӢҲлӢӨ. н”ҢлқјмҠӨнӢұмқҙлӮҳ кі л¬ҙмІҳлҹј 비көҗм Ғ л¶Җл“ңлҹ¬мҡҙ мҶҢмһ¬лҘј к°Җкіөн•ҳлҠ” лҚ° м Ғн•©н•©лӢҲлӢӨ. н•ҳм§Җл§Ң кі к°•лҸ„ мһ‘м—… мӢңм—җлҠ” лҚ” мһҗмЈј лӮ мқ„ к°Ҳм•„м•ј н• мҲҳ мһҲмҠөлӢҲлӢӨ.

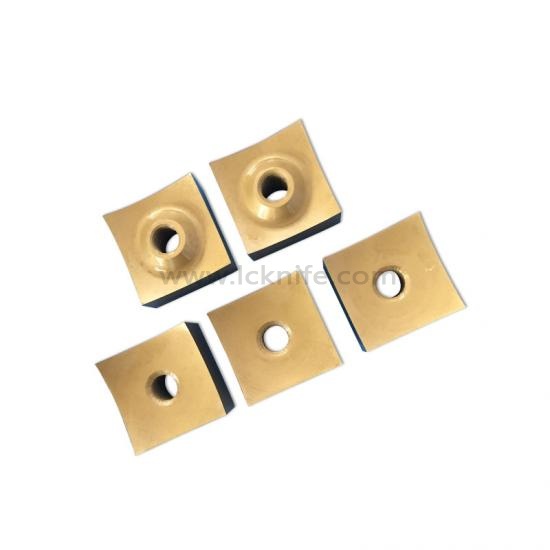

лҳҗ лӢӨлҘё мқёкё° мһҲлҠ” мҳөм…ҳмқҖ D2 лҳҗлҠ” Cr12MoVмҷҖ к°ҷмқҖ н•©кёҲ кіөкө¬к°•мһ…лӢҲлӢӨ. мқҙ к°•мқҖ мқём„ұ, лӮҙл§ҲлӘЁм„ұ, к·ёлҰ¬кі кІҪлҸ„к°Җ к· нҳ• мһҲкІҢ мЎ°нҷ”лҘј мқҙлЈ№лӢҲлӢӨ. лӘ©мһ¬, мў…мқҙ, к·ёлҰ¬кі мқјл¶Җ кёҲмҶҚкіј к°ҷмқҙ лӢЁлӢЁн•ң мһ¬лЈҢлҘј нҢҢмҮ„н•ҳлҠ” лҚ° мқҙмғҒм Ғмһ…лӢҲлӢӨ. нҠ№нһҲ D2лҠ” нғ„мҶҢмҷҖ нҒ¬лЎ¬ н•Ёлҹүмқҙ лҶ’м•„ лӮҙл§ҲлӘЁм„ұмқҙ л§Өмҡ° лӣ°м–ҙлӮ©лӢҲлӢӨ.

к·№н•ң нҷҳкІҪм—җм„ңлҠ” мҙҲкІҪ нҢҒмқҙлӮҳ кі мҶҚлҸ„к°•(HSS) лё”л Ҳмқҙл“ңк°Җ мӮ¬мҡ©лҗ©лӢҲлӢӨ. мқҙлҹ¬н•ң мҶҢмһ¬лҠ” кі мҳЁкіј кі н•ҳмӨ‘мқ„ кІ¬лҺҢлӮҙ лӣ°м–ҙлӮң м ҲмӮӯ м„ұлҠҘкіј нӣЁм”¬ кёҙ мҲҳлӘ…мқ„ м ңкіөн•ҳм§Җл§Ң, 비мҡ©мқҙ лҚ” л§Һмқҙ л“ӯлӢҲлӢӨ.

мқјл¶Җ л§һм¶Өнҳ• м Ғмҡ© 분야м—җм„ңлҠ” нҠ№м • л¶ҖмӢқ лҳҗлҠ” м„ұлҠҘ мҡ”кө¬ мӮ¬н•ӯмқ„ 충мЎұн•ҳкё° мң„н•ҙ нҠ№мҲҳ мҠӨн…ҢмқёлҰ¬мҠӨк°•мқҙлӮҳ 분л§җ м•јкёҲ мҶҢмһ¬к°Җ мӮ¬мҡ©лҗ©лӢҲлӢӨ.

кІҖмӮ¬ wechatпјҡ